Línea de extrusión de película solar EVA POE

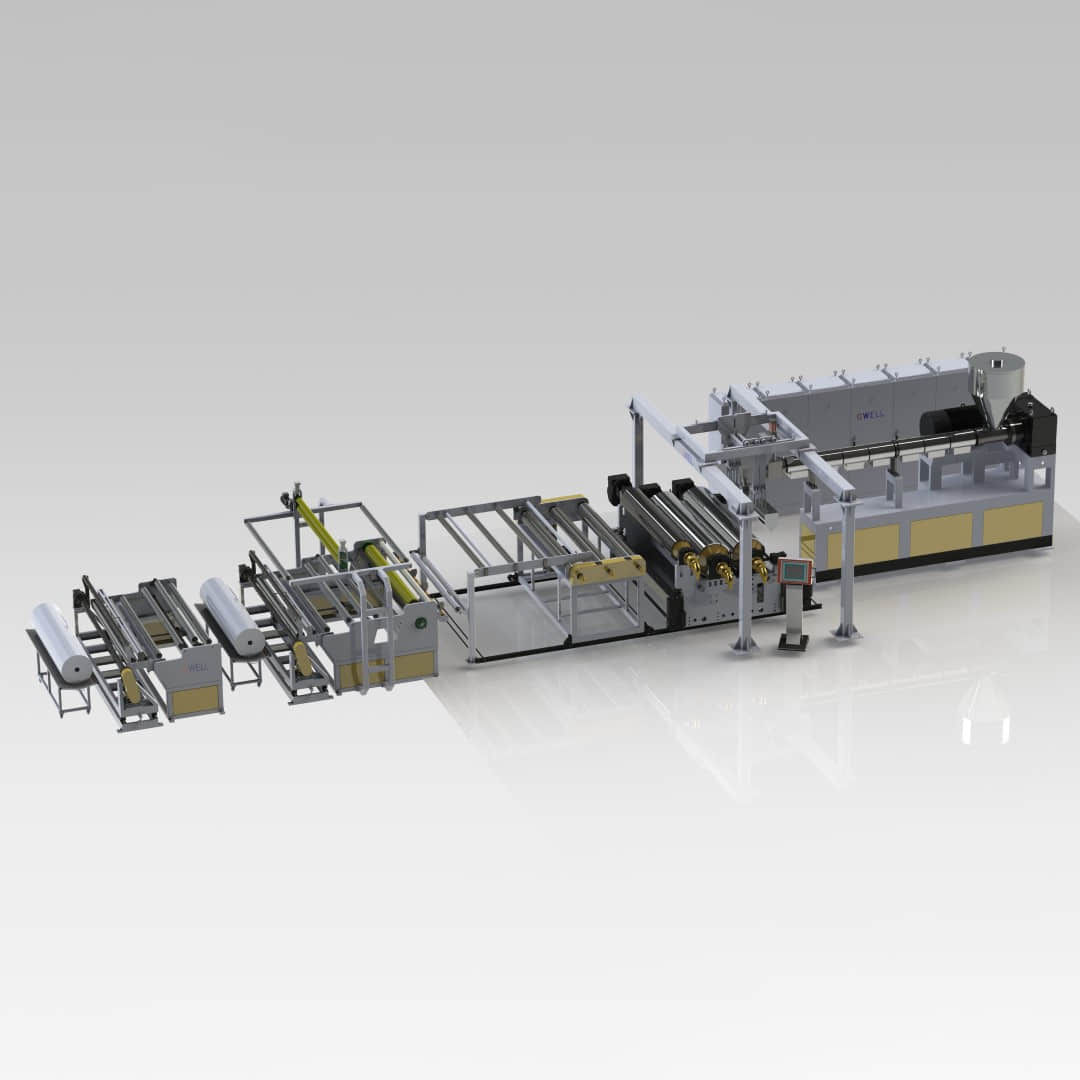

China GWELL has two EVA POE solar film extrusion lines: one is a single screw extruder that can produce EVA or POE film monolayers. The other is co-extrusion, which can produce either single-layer EVA or POE film, or EVA/POE/EVA three-layer film (EPE film). It will be according to the customer’s request.

Palabras clave: Línea de extrusión de láminas

Categoría:

Línea de extrusión solar

Descargar:

Descripción

The EVA Solar Film Line is a fully automated production line, which means it can operate continuously without any manual intervention, ensuring high efficiency and productivity. The machinery is equipped with advanced sensors and control systems that monitor the production process and make real-time adjustments to ensure consistency and high-quality output. The machinery is also designed with a user-friendly interface that enables easy operation and maintenance.

The EVA Solar Film Line is made with high-quality components, such as the extruder, which is made with a high-torque gearbox and efficient screw design that can handle high melting temperatures and produce uniform extrusion. The machinery also has a high-precision die, which can produce films with consistent thickness and width. The film cooling system is also designed with precision, which can effectively cool the film and prevent warping or shrinkage.

EVA film extrusion line components

- All parts can be customized.

- Extrusion system Customized thread combination structure to ensure high output.

- The forming system, select sincere molds and adjust product thickness at any time.

- Three-roller setting bearing, the error is controlled in the micron mirror roll-to-compression molding, independent servo control, and imported roller shaft.

- Traction winding: nitrile rubber roller traction, multi-station winding.

POE film production line introduction

- China GWELL as a film extrusion line manufacturer, POE has the general characteristics of thermoplastic elastomer, the soft chain curl structure of octene, and the crystalline ethylene chain as a physical cross-linking point, it has both excellent toughness and good processability. The price is low and the relative density is small, so the volume is cheap;

- Excellent heat resistance and cold resistance, wide operating temperature range.

- Good weather resistance and aging resistance. Because there is no unsaturated double bond in the molecular structure of POE plastic, it has excellent aging resistance.

- Oil resistance, compression permanent deformation resistance, and wear resistance are not very good. POE plastics have narrow molecular weight distribution, good fluidity, and good compatibility with polyolefins. Good fluidity can improve the dispersion effect of fillers and also improve the weld line strength of products.

The specific maintenance cycle of high-efficiency EVA solar film machine is as follows

1. Change the gearbox oil every 4000~5000 hours of operation, at least once a year;

2. Bearings, cardan shafts, etc. need to be greased regularly;

3. Check the coaxiality and wear of the rubber pad at the coupling every three months;

4. The oil filter element of the hydraulic system needs to be replaced every six months, and the pressure of the energy storage tank needs to be checked regularly;

5. The temperature control system of the water roller should clean the condenser and scale regularly, and the recommended period is half a year;

6. When the roller and cooling roller are not in use for a long time, they should be coated with anti-rust oil and wrapped with cotton cloth;

7. The traction rubber roller should be cleaned regularly with oil-free detergent, and anti-aging treatment should be done if it is not used for a long time;

8. The high-efficiency EVA solar film machine electric control cabinet should check the components regularly, and replace the aging or poor contact components in time;

9. The temperature is low in winter and the shutdown time is long. Before shutdown, the equipment with water should be drained to prevent the equipment from freezing (cracking).

EVA film machine introduction

EVA film is a high-viscosity film material sheet made of polymer resin (ethylene-vinyl acetate copolymer) as the main raw material, adding special additives, and processing with special equipment. It is also called a modified EVA clip in the industry. Adhesive glass film. Due to the superiority of EVA film in adhesion, durability, optical properties, etc., it is more and more widely used in current components and various optical products.

EVA POE solar film extrusion line introduction

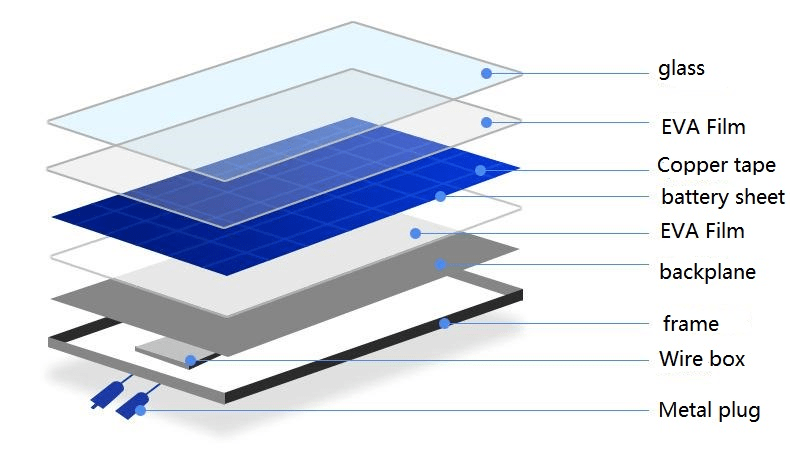

EVA is a thermosetting adhesive film that is used in the middle of laminated glass. EVA and POE encapsulation films are mainly used for the encapsulation of crystalline silicon and some thin-film solar cell modules. Due to the superiority of EVA and POE films in terms of adhesion, durability, and optical properties, they are more and more widely used. Used in current components and various optical products.

The EVA Solar Film Machine is a state-of-the-art machine that is designed to produce high-quality EVA (ethylene-vinyl acetate) solar film. The machine is an essential tool for manufacturers who need to produce solar film for a wide range of applications, including solar panels, photovoltaic modules, and other solar energy products. With its advanced technology and superior performance, the EVA Solar Film Machine is an excellent investment for manufacturers looking to produce high-quality solar film with precision and consistency.

One of the key attributes of the EVA Solar Film Machine is its ability to produce solar film with exceptional transparency and adhesion. The machine is designed to extrude EVA resin with a high degree of precision, resulting in solar film that has excellent transparency and adhesion. This makes them ideal for applications where visibility is critical, such as solar panels and photovoltaic modules.

Another advantage of the EVA Solar Film Machine is its ability to produce solar film with excellent heat resistance. EVA solar film is known for its exceptional heat resistance, making it an ideal material for use in solar energy applications. The machine is designed to extrude EVA resin with a high degree of consistency, ensuring that each film is produced to the desired thickness and with the desired properties.

The EVA Solar Film Machine is also highly versatile, capable of producing film with a wide range of thicknesses and sizes. This versatility makes it an ideal choice for manufacturers who need to produce a variety of solar film with different specifications.

In addition to its precision and versatility, the EVA Solar Film Machine is also highly efficient. The machine is designed to operate at high speeds, allowing for the production of large quantities of solar film in a short period of time. This high-speed operation reduces manufacturing costs and increases productivity, making it an excellent investment for manufacturers looking to improve their production efficiency.

The EVA Solar Film Machine is also designed with safety in mind. The machine is equipped with a range of safety features such as emergency stop buttons, safety guards, and sensors that prevent accidents and ensure that the machine operates safely and efficiently. This is essential in manufacturing environments where safety is a top priority.

The EVA Solar Film Machine is also designed for easy maintenance and servicing. The machine is constructed from high-quality materials and is designed to withstand the rigors of daily use in a manufacturing environment. It is easy to clean and maintain, and requires minimal downtime for servicing, ensuring that it is always available when needed.

Overall, the EVA Solar Film Machine is an essential tool for manufacturers who need to produce high-quality, high-performance solar film efficiently and reliably. Its precision, versatility, and efficiency make it an ideal choice for a wide range of applications, while its advanced safety features and reliable operation ensure that it is a machine that can be relied on day after day. If you are looking for a high-quality solar film extrusion solution, the EVA Solar Film Machine is the perfect choice.

EVA Solar Encapsulation Film Production Line Technical Parameters

GWELL Machinery has always occupied more than 80% of the market share in the field of EVA photovoltaic film equipment. The company has been deeply involved in the photovoltaic film industry for decades, and the equipment has been designed and optimized for thousands of times. The in-process yield rate and the degree of equipment automation have been widely recognized by various leading companies. In this equipment field, due to the company’s scale advantages and resource advantages, in the field of photovoltaic film, GWELL Machinery is no longer limited to equipment development, and has a very deep understanding of upstream suppliers and downstream customers.

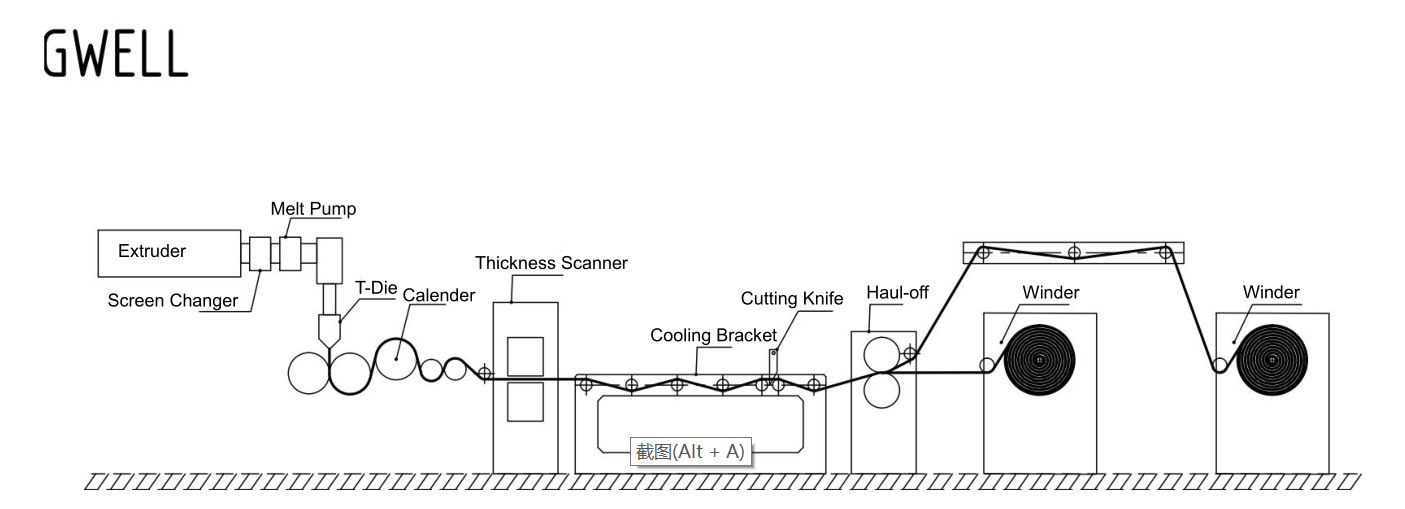

EVA POE Solar Film Extrusion Line Process Flows

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Thickness Scanner —-Cooling Bracket —-Cutting Knife —- Haul-off —-Winder

EVA POE Solar Film Extrusion Line adopts the casting process to produce EVA POE solar cell encapsulation film machine. The primary raw material is imported vinyl acetate copolymer EVA POE, and imported plastic additives are added, which are heated, poured, and extruded. The film is not sticky at room temperature, and the cutting operation is convenient. Thermal cross-linking curing and adhesion-enhancing reactions occur after hot pressing, resulting in a permanent bond and seal. It is a new type of thermosetting hot melt adhesive film.

Solar cell adhesive film is used for solar cell encapsulation. After lamination and curing, it is bonded and sealed, which has the functions of high light transmittance, preventing water vapor penetration, high and low-temperature resistance, and anti-ultraviolet light. to ensure the stable and efficient use of battery components, is a durable and reliable packaging material. EVA POE film production line adopts the casting process to produce EVA POE solar cell encapsulation film. EVA and POE can be shared on one production line. EPE film=EVA+POE+EVA, which is a three-layer co-extruded solar film. Compared with single-layer EVA and POE films, it achieves high performance and saves costs.

Compared with EVA laminating machine, the most significant advantage of the POE laminating machine is a low water vapor transmission rate and high volume resistivity, which ensures the safety and long-term aging resistance of components in high temperature and high humidity environments, and ensures long-term use of components. Specifically, the superior performance of POE film over the EVA film machine is that the POE film machine is a copolymer of ethylene and octene, which is a saturated aliphatic chain structure with fewer carbon atoms in the molecular chain, showing good weather resistance and UV aging resistance. It has excellent heat and low-temperature resistance, so POE film has better aging resistance than EVA film machines.

The EVA film production line for photovoltaic cell encapsulation developed is a special energy-saving, high-efficiency, innovative, and cost-effective extrusion production line. It is currently China’s hottest EVA film extrusion line for photovoltaic cells. Production equipment.

The EVA photovoltaic film under the EVA POE solar film production line generally requires a thermal shrinkage rate of less than 5% to meet the requirements of battery packaging. Shrinkage limits traditional EVA photovoltaic film extrusion production equipment. Production speed is almost entirely dependent on the extrusion speed of the melt out of the die, resulting in an inability to increase production speed. A breakthrough was made in the high-speed extrusion technology of low-shrinkage EVA photovoltaic film. The developed stress relief device can effectively eliminate the residual stress generated during film stretching and online production, and better solve the problem of thermal shrinkage of EVA film.

The EVA POE solar film extrusion line has undergone several iterations. The structure and debugging process of EVA solar film machines have been polished for decades, forming a mature production system in the photovoltaic industry. China Plastic Extruder Supplier GWELL can provide customers with a full range of customized services for EVA solar film production lines from raw material procurement, formulation consultation, related auxiliary equipment matching, debugging process training, etc.

EVA solar cell adhesive film is used for solar cell packaging. After lamination and curing, it is bonded and sealed. It has the functions of high light transmittance, preventing water vapor penetration, high and low-temperature resistance, and anti-ultraviolet light for cell components, ensuring the stability and efficiency of battery modules. It is a durable and reliable packaging material.

EVA POE film production line performance characteristics

- The drool extruder adopts EVA single screw extrusion, and the screw barrel constant temperature circulating water cooling system solves the technical difficulties of EVA plasticization and non-crosslinking.

- The roller body adopts double-sided embossing, and solves the technical difficulty of sticking the film to the roller.

- The cooling part adopts cooling roller and stress-relieving cooling bed to make the film run smoothly and fully shape, to ensure that the shrinkage rate is less than 3%.

- The whole line adopts PLC automatic control to realize the operation of man-machine interface.

- The production line is equipped with an online quality monitoring and control system to ensure the qualified rate of products.

- Micro tension winder, the line speed of the whole machine can reach 18m/min

EVA/POE Solar film extrusion line Advantages

- Global market share reaches 90%, including China, America, India, Turkey, and so on.

- The line speed of the EVA/POE solar film line can reach 18m/min.

- Cooling parts to ensure shrinkage rate is less than 3%.

- The special winder ensures micro tension and realizes automatic relaxation and cutting.

- Comparison and introduction of POE and EVA film, EVA/POE/EVA film

- The drooling extruder adopts multi-machine co-extrusion POE single-screw extrusion, and the screw barrel constant temperature circulating water cooling system.

- The roller body adopts double-sided embossing.

- The cooling part adopts a cooling roller and stress-relieving cooling bed to make the film run smoothly and entirely shape to ensure that the shrinkage rate is less than 3%.

- The whole line adopts PLC automatic control to realize the operation of the man-machine interface.

- The production line is equipped with an online quality monitoring and control system to ensure the qualification rate of products.

- Development and design of micro-tension winders.

EVA POE solar film extrusion line product advantages

- High transparency and high adhesion can be applied to various interfaces, including glass, metal, and plastics such as PET.

- Good durability can resist high temperatures, moisture, ultraviolet rays, and so on.

- Easy to store. Stored at room temperature, the adhesion of EVA is not affected by humidity and absorbent films.

- Compared with PVB, it has a stronger sound insulation effect, especially for high-frequency sound effects.

- Low melting point, easy to flow, suitable for laminating process of various glass, such as patterned glass, tempered glass, curved glass, and so on.

The EVA film production line adopts the casting process to produce EVA solar cell encapsulation film. EVA solar cell film is used for solar cell encapsulation. After the lamination is cured, it is laminated and sealed, which has high light transmittance to the battery components and prevents the penetration of water vapor. , high and low-temperature resistance, anti-ultraviolet, and other functions, to ensure the stable and efficient use of battery components, is a durable and reliable packaging material. EVA packaging film production line is in a monopoly global leading position.

Features of EVA Film Extrusion Line

- EVA single-screw extruder is used for extrusion, and the barrel constant temperature circulating water cooling system solves the technical problems of EVA plasticization and non-crosslinking.

- The roller body adopts double-sided embossing, which solves the technical difficulties of the rubber roller.

- The cooling part adopts cooling rollers and stress-relieving cooling beds so that the film runs smoothly and is completely shaped, and the shrinkage rate is guaranteed to be less than 3%.

- The whole line adopts PLC automatic control to realize man-machine interface operation.

- The production line is equipped with an online quality monitoring system to ensure the qualification rate of products.

- Patented micro-tension winding machine, the line speed of the entire production line can reach 14m/min.

- Low-temperature precision extrusion technology, stable control at 75°C during the process from extrusion to the film release.

- It breaks through the limitation of shrinkage rate control on the production line speed; the production line speed can reach 7 m/s, the shrinkage rate can be controlled within 2%, and the production efficiency and quality are doubled.

- Tempering stress relief devices, saving energy, and reducing consumption by more than 50%.

- Mature online process and electrical control system to ensure long-term stable operation of the equipment.

- The procedure is simple and convenient, and the product quality is easier to grasp.

- This equipment has mature technology and is widely used in the field of solar cells. The production line speed is about 8m/min. The winder can be semi-automatic or fully automatic according to customer requirements. The equipment has been awarded the utility model product, which solves the technical defects and guarantees quality.

Feature of EVA/POE Solar film extrusion line

- Film Layers: Depending on the finished film, there are two types of extruders that can produce EVA or POE film monolayers. The other is co-extrusion. It can not only produce EVA or POE film single layer, but also can produce EVA/POE/EVA three-layer film (EPE film). It will be according to customer’s request.

- Extruder: A special single-screw extruder for EVA/POE is used, the temperature difference between the screw and barrel is ±1°C, and the circulating water cooling system ensures that the longitudinal thickness of the EVA/POE film is uniform. And better plasticization and non-crosslinking.

- Screen changer: The advantage of adopting the plate type screen changer is equipped to filter impurities. Compared with the column-type screen changer, the plate-type screen changer has fewer accumulated materials, and fewer materials stored in the screen changer after shutdown and restart, which means less waste. It is convenient to change and clean the screen. It will decrease the cost of the EVA/POE raw material.

- Melt pump: With higher accuracy, forming closed-loop control with the extruder, and the pressure fluctuation accuracy behind the pump is ± 0.1MPa; The pressure detection sensor, with accurate detection and fast response, which is one of the keys to ensure the event of longitudinal thickness;

- T-die: there are two kinds of T-die, the one is manual T-die, and the other is automatic T-dies. one of the important differences between them is tolerance. And it can ensure the even of cross side.

- Calendar: The strength of the roller shall ensure that the temperature fluctuation accuracy of the roller surface is ≤± 1 degree, and the straightness and radial runout of the roller surface is ≤± 0.01mm. The roller body adopts double-sided embossing and solves the technical difficulties of the film sticking to the roller.

- Cooling part: Dedicated cooling rolls and stress-relieving cooling bed make the film run smoothly, form fully, and ensure that the shrinkage rate is less than 3%.

- Thickness scanner: To match the automatic T-die.Scan the thickness of the film, and reflect T-die. Then T-die can modify automatically. It can decrease labor costs.

- Winder: It can decrease the tension and ensure side winding is smooth.

- Automatic operation: The whole line adopts PLC automatic control to realize the operation of the man-machine interface. It is easy and automatic to operate.

EVA film(Ethylene):

- Because of the application of solar film, EVA film has good durability to resist high temperatures, ultraviolet rays, moisture, and so on.

- EVA film can store at room temperature. Although long time, the adhesion EVA will not change.

- EVA film’s high adhesion can not only adapt to encapsulation but also dressing in the field.

POE film(polyolefin):

In addition to the characteristics of EVA film, the biggest advantages of the POE film produced are low water vapor transmission rate and high volume resistivity, which ensures the safety and long-term aging resistance of the module under high temperature and high humidity environment. Can be used longer than EVA film. Therefore, the performance of POE film is better than that of EVA film.

POE can replace rubber, flexible PVC, EPDM, EPR, EMA, EVA, TPV, SBC, and LDPE, and other materials, used in different products, such as automotive baffles, flexible conduits, conveyor belts, printing cylinders, sports shoes, wire and cable, auto parts, durable goods, extrusion parts, compression molding parts, sealing materials, pipe fittings and fabric coatings, etc., can also be used as a low-temperature impact modifier to improve the low-temperature impact resistance of PP, and can also be used as a low-temperature impact modifier. It is used in the automotive field as a thermoplastic elastomer.

POE can be processed and formed using common thermoplastic processing equipment. The forming processing temperature and processing pressure should generally be slightly higher and can be processed at extremely high processing speeds. It can be injection molded, extruded, or processed into a sheet or film by a calendar, and can be blow molded, and thermoforming can be used to manufacture products with complex shapes. Various pigments can be added to make different colors as needed.

EVA/POE/EVA film:

EVA/POE/EVA film has three layers, including EVA and POE film advantages and lower cost than POE film.

What are the difficulties in the manufacture of EVA photovoltaic film

EVA photovoltaic film is different from other EVA products and puts forward higher requirements for raw materials, processes and equipment.

1. EVA sensitivity to temperature

One of the biggest characteristics of EVA raw materials is that it is very sensitive to temperature. When the resin is plasticized in the screw, if the temperature is too high or the temperature is too low, the products will be scrapped immediately. The precise control of temperature will directly affect the upper limit of quality of the final product. For this, GWELL Machinery has designed a special screw for EVA, so that EVA can be completely plasticized during the plasticizing process, and there will be no over-plasticization caused by local over-temperature. Not only the temperature is very important in the yield rate of the product, but also the speed of the production line is extremely important. Ten years ago, the EVA photovoltaic film could not have a very high line speed. At that time, the line speed was only 2 meters per meter. In about seconds, after continuous optimization, the speed of the production line has now reached an astonishing 16m/min. It can be said that it is not inferior to the tens of millions of equipment in Germany. This is also an important reason why GWELL has gradually become the leading company in this market in the past ten years.

2. Strict control of winding tension on EVA

Don’t underestimate the influence of the internal stress of EVA photovoltaic film on the quality of photovoltaic film. EVA photovoltaic film is in the hands of downstream module manufacturers. If a film is bulged, the entire module will be scrapped, which is undoubtedly very heavy for module manufacturers. The second reason for this phenomenon is that The internal long force of the EVA film is too large, resulting in excessive stretching. There are strict requirements for the winding tension control of the equipment. The winder of GWELL machinery can strictly control the tension of the product within 20N, which ensures the yield of the product. At the same time, the functions realized by the fully automatic winder developed by GWELL can minimize the waste of products.

EVA, POE photovoltaic film production line

EPE=EVA+POE+EVA is a three-layer co-extruded solar film. Compared with single-layer EVA and POE films, it achieves high performance and saves costs.

General description of the solar film The EVA POE Solar Film Extrusion Line Machinery Co., Ltd. adopts the casting process to produce EVA POE solar cell encapsulation film. The EVA film production line can also produce POE film at the same time, realizing a dual-purpose machine, and also taking into account the three-layer co-extrusion of EVA, POE, and EVA, which improves the multiple uses of the product and meets the different needs of customers. At present, the main models of film equipment are divided into 160 single machines, 180 single machines, double 160 co-extrusion, double 180 co-extrusion, and 160/180 co-extrusion types.

China GWELL is a high-tech enterprise integrating management, R&D, design, manufacturing, and commissioning. It can provide high-efficiency and high-quality pre-feasibility research, program demonstration, program design, equipment commissioning and acceptance, and equipment operation training service.

In recent years, GWELL’s equipment has been exported all over the world and exported to Russia, Spain, Turkey, Iran, South Korea, and Indonesia. We customize according to the unique requirements of customers in each industry to make products more intelligent and user-friendly while helping customers reduce costs and improve efficiency.

Parámetro

| Tipo del extrusor | Extrusor de solo tornillo GWS150,GWS160,GWS180 | Coextrusión GWS160 GWS160,GWS180 GWS160,GWS180 GWS180 |

| Materia prima | EVA, POE | EVA, POE |

| Capas | EVA o POE de una sola capa | EVA o POE de una sola capa, EVA/POE/EVA tres capas |

| Anchura neta | 2000mm,2400mm,2600mm | |

| Rango de espesor | 0,2mm-1mm | |

| Max velocidad lineal | 10 m/min,12 m/min,16 m/min,18 m/min | |

| Aplicación | Película de EVA/POE para la encapsulación solar | |

Aplicación

Debido a la adherencia superior de la película de EVA/POE, a la durabilidad, y a las características ópticas, que se utiliza principalmente para

- China GWELL como fabricante de línea de extrusión de película, película de capa intermedia de vidrio EVA, los productos son ampliamente utilizados en: procesamiento profundo de vidrio especial como vidrio laminado plano de seguridad, vidrio laminado curvado, vidrio laminado de proceso, vidrio laminado que cambia de color, vidrio inteligente conductor, células solares y así sucesivamente.

- Película fundida adhesiva de fusión en caliente, película en relieve, los productos son ampliamente utilizados en: productos de higiene: bata quirúrgica médica, película de pañales para bebés, película inferior de servilleta sanitaria para mujeres, película de pañales para adultos, película de almohadilla para mascotas, sábana desechable, etc.

- Necesidades diarias: paraguas, impermeables, chaquetas de traje, varios manteles, gorros de ducha, cortinas de ducha, delatones, fundas para sillas, etc.

- Suministros de embalaje: cubierta de polvo para computadoras y aparatos eléctricos, envases blandos para cosméticos, bolsas de compras, bolsas de regalo, bolsas de archivos, etc.

Cliente

Sobre Gwell

La innovación impulsa el progreso de la empresa. Confiando en la tecnología fuerte del grupo, fuerza del equipo y alcohol de la innovación, Gwell está confiado al desarrollo de productos de alta tecnología y del mercado internacional. Gwell también intercambia y coopera activamente con instituciones de investigación científica de clase mundial. Las nuevas tecnologías, los nuevos procesos y los nuevos productos desarrollados por Gwell son ampliamente utilizados en los materiales de construcción (máquina hueco de la protuberancia de la hoja de los PP, máquina óptica de la protuberancia de la PC), aparatos electrodomésticos (máquina de la protuberancia del piso del SPC), empaquetando (máquina de la protuberancia de la hoja del ANIMAL DOMÉSTICO, máquina, máquina de la protuberancia de la película de EVOH),

Tratamiento médico (máquina rígida de la protuberancia de la hoja del PVC), automóviles (máquina de la protuberancia de la película de TPU, máquina de la protuberancia de la película de PVB), nueva energía (máquina solar de la protuberancia de la película de EVA), espacio aéreo (máquina de la protuberancia de la película de TPU), tránsito del carril (máquina impermeable de la protuberancia de la película) y otros campos, estrechamente relacionados con la vida humana.

Producto relacionado

Los principales componentes de la línea de producción de extrusión de láminas de PC se seleccionan entre productos de alta calidad de todo el mundo (como tornillos, barriles, rodillos, etc.), y su proceso de producción es integral. Como excelente proveedor de extrusoras de plástico, el conjunto completo de la línea de producción de GWELL se ha acercado a los estándares de productos de alta calidad a nivel mundial.

Como pioneros en la tecnología de máquinas para la producción de películas de intercapa PVB, nos especializamos en ofrecer sistemas de vanguardia diseñados para la fabricación de películas de intercapa PVB de alto rendimiento. Nuestras máquinas para la producción de películas de intercapa PVB están diseñadas para cumplir con los estándares globales de la industria, combinando precisión, eficiencia y sostenibilidad.

Durante más de una década, GWELL ha sido pionera en tecnologías de extrusión avanzadas para películas de encapsulación solar. Nuestros sistemas producen películas de EVA, POE e innovadoras películas de EPE de alto rendimiento que protegen las células solares a la vez que maximizan la eficiencia del módulo.

Preguntas frecuentes

Cuál es el principal negocio de GWELL?

Puedo ir de excursión a la fábrica de GWELL?

Cuáles son los servicios para la compra de equipos en GWELL?

Qué tipos de máquinas de extrusión de plástico están disponibles en GWELL?

Qué es la línea de extrusión de láminas APET PETG CPET?

De dónde viene Gwell?

Hay algún soporte técnico para la máquina de extrusión que necesite?

Nuestro servicio estará siempre a su disposición durante toda la vida de la línea de extrusión, por lo que si desea conocer cualquier otro soporte técnico, póngase en contacto con nosotros lo antes posible.

CLASIFICACIÓN