Línea de extrusión de película multicapa EVOH

China GWELL as China Plastic Extruder Supplier, EVOH multi-layer film extrusion line adopts precision dispensing technology, proportional metering, fixed flow channel, more accurate layering and more stable pressure. The whole line adopts man-machine interface display, PLC control, frequency conversion speed regulation, online powder cleaning, and automatic cleaning.

Palabras clave: Línea de extrusión de láminas

Categoría:

Línea de extrusión de película

Descargar:

Descripción

EVOH multi-layer film extrusion line features

- The EVOH multi-layer film extrusion line has the “one-key acceleration” function, which allows the equipment to realize low-speed adjustment and high-speed production, which greatly reduces the waste of raw materials caused by the adjustment process. Intelligent advanced control system, network The transmission speed is fast, which greatly reduces the transmission error of information, and makes the speed, pressure and material transportation of the equipment more stable.

- The winding part adopts servo control, which is more accurate, and has the speed synchronization function with the whole machine, which makes the winding more convenient, simpler and safer.

- Through centralized control, EVOH multi-layer film extrusion line can browse all the information of the equipment on one screen, such as current, pressure, speed, temperature, vacuum pressure, etc., making the operation easier.

- The whole set of China EVOH multi-layer film extrusion line adopts the international first-line brand-Siemens frequency conversion servo control and Ethernet conduction technology control to achieve high efficiency, high precision, high stability and high security. Quickly locate errors and enable remote maintenance when equipment fails. Channel-level diagnosis and error analysis can be achieved through HMI, which greatly reduces debugging and production downtime. The high-digital system makes debugging easier and maintenance more convenient.

- Complete after-sales service system, from equipment installation and debugging to high-quality product manufacturing, and provide lifetime technical support, so that customers have no worries.

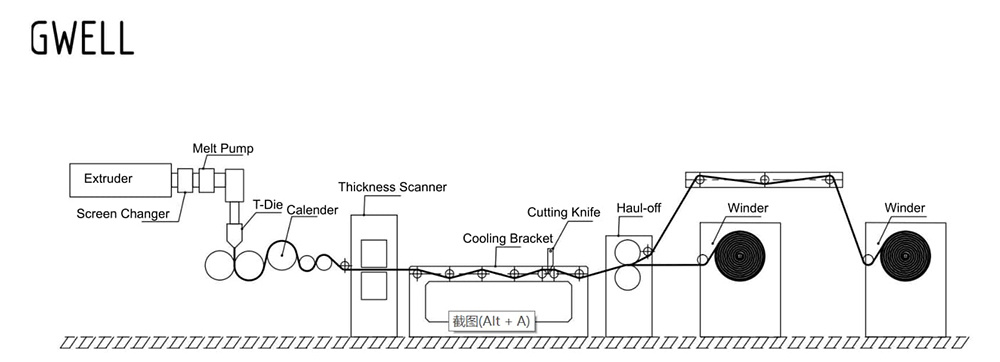

EVOH multi-layer film extrusion line Process Flows

Extruder —- Screen changer —– Melt pump —– T-die —— Calender —– Thickness Scanner —-Cooling Bracket —-Cutting Knife —- Haul-off —-Winder

EVOH is a crystalline polymer with a chain structure, which integrates the good processability of ethylene polymer and the extremely high gas barrier of vinyl alcohol polymer. It is a new barrier material. Its gas barrier is 100 times higher than PA (polyamide), 10000 times higher than PE and PP, and more than ten times higher than PVDC (polyvinylidene chloride).

In addition, EVOH has excellent transparency, gloss, mechanical strength, flexibility, wear resistance, cold resistance and surface strength. At the same time, EVOH has the highest thermal stability among high-performance barrier resins. This property makes the waste produced in processing reusable.

The multi-layer extruded composite film made of ordinary plastics and high barrier plastics can not only significantly improve the barrier performance, but also help to play the role of each component, and obtain a film with good comprehensive performance and low cost.

EVOH, as a high barrier material, is often extruded with a variety of resins in multiple layers and is used for the packaging of beverages, dairy products, fruit juices, beverages, and a variety of foods. For example, at present, many domestic aquatic products companies export seafood with PE/TIE/EVOH/PA/EVOH/TIE/PE seven-layer coextrusion membrane vacuum packaging.

EVOH has always been the most widely used high barrier material. In addition to the non-stretching type, the film type of this material also includes the biaxial stretching type, aluminum evaporation type, adhesive coating type, etc. Among the biaxial stretching type, there are heat-resistant types for aseptic packaging products.

The barrier performance of EVOH depends on the ethylene content. Generally speaking, when the ethylene content increases, the gas barrier decreases, but it is easy to process.

EVOH is characterized by an excellent gas barrier and excellent processability. In addition, it has excellent transparency, gloss, mechanical strength, scalability, wear resistance, cold resistance and surface strength.

The EVOH Multi-Layer Film Extrusion Line – a cutting-edge product designed to provide manufacturers with a reliable and efficient solution for producing high-quality multi-layer films. This machine is specifically designed for extruding ethylene vinyl alcohol (EVOH) barrier films, which are used in a wide range of applications such as food packaging, medical packaging, and industrial packaging. With its advanced features and superior performance, the EVOH Multi-Layer Film Extrusion Line is an essential tool for manufacturers looking to produce high-quality films with precision and consistency.

One of the key attributes of the EVOH Multi-Layer Film Extrusion Line is its ability to produce multi-layer films with exceptional barrier properties. The machine is equipped with advanced technology that allows for the precise control of each layer’s thickness, ensuring that the film’s barrier properties are optimized. This is essential for applications where high levels of protection are required, such as in food and medical packaging.

Another advantage of the EVOH Multi-Layer Film Extrusion Line is its versatility. The machine can produce a wide range of films with different layer configurations and thicknesses, depending on the specific requirements of the application. This versatility makes it an ideal choice for manufacturers who need to produce a variety of products with different specifications.

In addition to its precision and versatility, the EVOH Multi-Layer Film Extrusion Line is also highly efficient. The machine is designed to operate at high speeds, allowing for the production of large quantities of film in a short period of time. This high-speed operation reduces manufacturing costs and increases productivity, making it an excellent investment for manufacturers looking to improve their production efficiency.

The EVOH Multi-Layer Film Extrusion Line also offers a range of advanced features that ensure its reliable and safe operation. The machine is equipped with automatic control systems that monitor and adjust key parameters such as temperature, pressure, and thickness during the extrusion process. This ensures that the film is produced to the desired specifications every time, with no variation or defects.

Safety is also a top priority for the EVOH Multi-Layer Film Extrusion Line. The machine is equipped with a range of safety features such as emergency stop buttons, safety guards, and sensors that prevent accidents and ensure that the machine operates safely and efficiently. This is essential in manufacturing environments where safety is a top priority.

The EVOH Multi-Layer Film Extrusion Line is also designed for easy maintenance and servicing. The machine is constructed from high-quality materials and is designed to withstand the rigors of daily use in a manufacturing environment. It is easy to clean and maintain, and requires minimal downtime for servicing, ensuring that it is always available when needed.

EVOH multi-layer film extrusion line Composition

- The EVOH multi-layer film extrusion line consists of 4 extruders, which can produce 4-layer, 5-layer, 7-layer, and other high-barrier films.

- Using precision distribution technology, proportional measurement, fixed flow channel, more accurate stratification and more stable pressure. The thickness error of EVOH layer is controlled by ±0.015mm.

- Adopt melt metering control, realize closed-loop control in extruder, and extrude more uniformly.

- The EVOH multi-layer film extrusion line adopts human-machine interface display, PLC control, frequency conversion speed regulation, and online powder cleaning to realize automation and cleaning.

- Three-roller arrangement: vertical type structure, suitable for processing materials of various thicknesses.

- Large winding diameter, frequency conversion drive, constant tension control.

GWELL as China Plastic Extruder Supplier, EVOH multi-layer film extrusion line continues the previous advantages of high output and low energy consumption, and at the same time, it keeps pace with the times and has a higher cost performance.

Since its establishment, China GWELL has been focusing on the R&D and production of plastic sheet extrusion production equipment. In the continuous innovation practice, the extrusion equipment has been improved to make the performance better and the structure more user-friendly.

Parámetro

| Tipo del extrusor | Coextrusión GWS165, combinación GWS75 | |

| Materia prima | PE, PA, EVOH, TPEE | |

| Anchura neta | 1400-1600mm | |

| Rango de espesor | 0,08-0,35mm | |

| Capacidad | 250-400 kg/h | |

Aplicación

- En el campo del envasado, EVOH se convierte en una capa de barrera intermedia de película compuesta, que se utiliza en todos los envases duros y blandos;

- En la industria alimentaria, se utiliza para envases asépticos, latas calientes y bolsas de cocción, envases de productos lácteos, carne, jugo de fruta enlatado y condimentos;

- En productos no alimentarios, se utiliza para envasar disolventes, productos químicos, piezas estructurales de aire acondicionado, revestimiento de barriles de gasolina, componentes electrónicos, etc.

- En términos de envasado de alimentos, los recipientes de plástico EVOH pueden reemplazar completamente los recipientes de vidrio y metal.

- Muchas empresas nacionales de productos acuáticos exportan mariscos con envasado al vacío de membrana de coextrusión de cinco capas PE/EVOH/PA/EVOH/PE.

- Mientras se acelera la investigación de películas compuestas de EVOH, la orientación a la tracción de EVOH también se está estudiando en el extranjero. El rendimiento de la barrera de gas de las nuevas películas de EVOH es tres veces mayor que el de las películas de EVOH no tensadas de alto rendimiento existentes.

- Además, EVOH también puede recubrirse sobre otros materiales de embalaje de resina sintética como material de barrera para mejorar el rendimiento de la barrera.

Cliente

Sobre Gwell

La innovación impulsa el progreso de la empresa. Confiando en la tecnología fuerte del grupo, fuerza del equipo y alcohol de la innovación, Gwell está confiado al desarrollo de productos de alta tecnología y del mercado internacional. Gwell también intercambia y coopera activamente con instituciones de investigación científica de clase mundial. Las nuevas tecnologías, los nuevos procesos y los nuevos productos desarrollados por Gwell son ampliamente utilizados en los materiales de construcción (máquina hueco de la protuberancia de la hoja de los PP, máquina óptica de la protuberancia de la PC), aparatos electrodomésticos (máquina de la protuberancia del piso del SPC), empaquetando (máquina de la protuberancia de la hoja del ANIMAL DOMÉSTICO, máquina, máquina de la protuberancia de la película de EVOH),

Tratamiento médico (máquina rígida de la protuberancia de la hoja del PVC), automóviles (máquina de la protuberancia de la película de TPU, máquina de la protuberancia de la película de PVB), nueva energía (máquina solar de la protuberancia de la película de EVA), espacio aéreo (máquina de la protuberancia de la película de TPU), tránsito del carril (máquina impermeable de la protuberancia de la película) y otros campos, estrechamente relacionados con la vida humana.

Producto relacionado

Los principales componentes de la línea de producción de extrusión de láminas de PC se seleccionan entre productos de alta calidad de todo el mundo (como tornillos, barriles, rodillos, etc.), y su proceso de producción es integral. Como excelente proveedor de extrusoras de plástico, el conjunto completo de la línea de producción de GWELL se ha acercado a los estándares de productos de alta calidad a nivel mundial.

Como pioneros en la tecnología de máquinas para la producción de películas de intercapa PVB, nos especializamos en ofrecer sistemas de vanguardia diseñados para la fabricación de películas de intercapa PVB de alto rendimiento. Nuestras máquinas para la producción de películas de intercapa PVB están diseñadas para cumplir con los estándares globales de la industria, combinando precisión, eficiencia y sostenibilidad.

Durante más de una década, GWELL ha sido pionera en tecnologías de extrusión avanzadas para películas de encapsulación solar. Nuestros sistemas producen películas de EVA, POE e innovadoras películas de EPE de alto rendimiento que protegen las células solares a la vez que maximizan la eficiencia del módulo.

Preguntas frecuentes

Cuál es el principal negocio de GWELL?

Puedo ir de excursión a la fábrica de GWELL?

Cuáles son los servicios para la compra de equipos en GWELL?

Qué tipos de máquinas de extrusión de plástico están disponibles en GWELL?

Qué es la línea de extrusión de láminas APET PETG CPET?

De dónde viene Gwell?

Hay algún soporte técnico para la máquina de extrusión que necesite?

Nuestro servicio estará siempre a su disposición durante toda la vida de la línea de extrusión, por lo que si desea conocer cualquier otro soporte técnico, póngase en contacto con nosotros lo antes posible.

CLASIFICACIÓN

Anterior

Siguiente

Anterior

Siguiente